Welcome to East Bay International (Pvt) Ltd

Where Quality Meets Sustainability in Seafood Processing

01

Premium Quality Seafood

Our products are responsibly sourced from Sri Lanka, ensuring the freshest, finest seafood.

Competitive Pricing

02

We employ an optimized pricing strategy to give you the best value.

Certified Quality

03

Our products meet strict certification standards, ensuring consistent quality and safety.

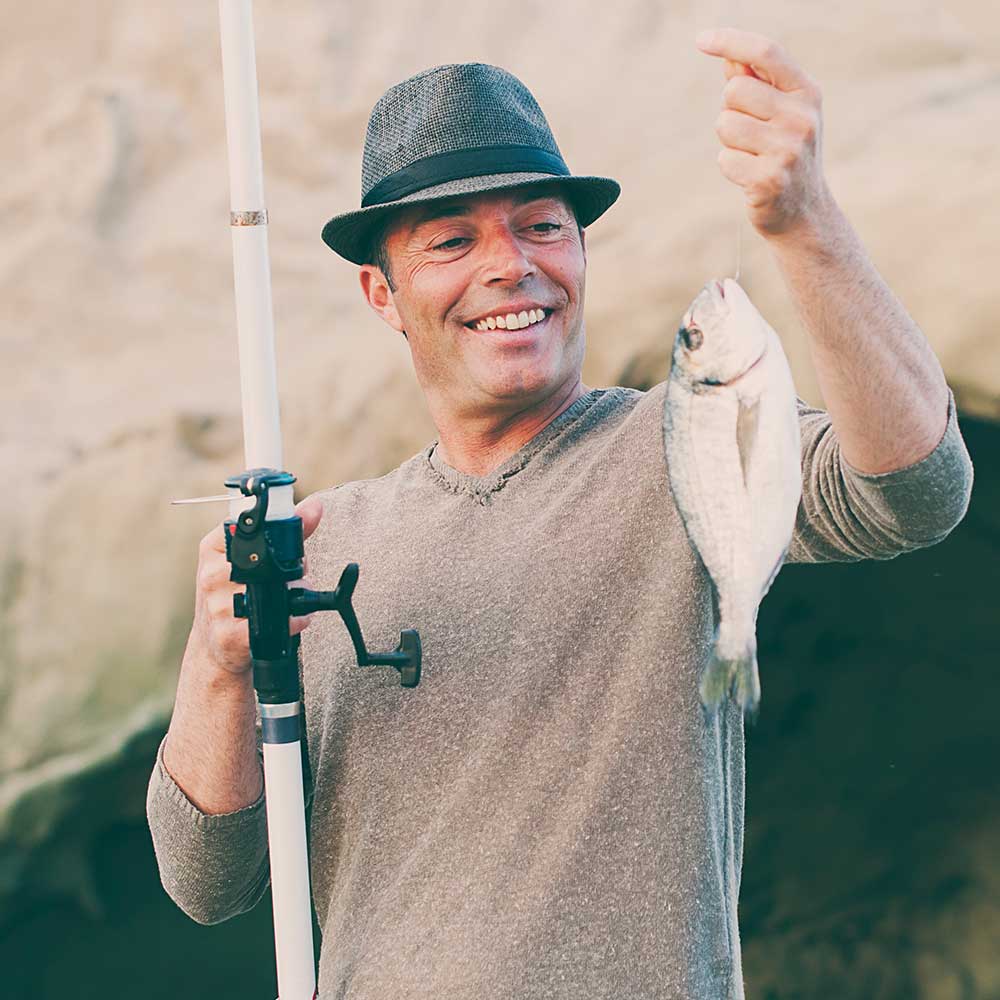

We Help Existing Anglers Improve Their Skills

Sri Lanka is endowed with an enormous stock of fishing resources – almost incalculable – thanks to its territorial waters covering an expanse of 21,500sq. km., the UN-Mandated Exclusive Economic Zone of 517 000sq.km., 260 000ha of freshwater bodies, 158 000ha of lagoons & estuaries, 71 000ha of mangrove zones, mudflats & salt marshes, and the growing aquaculture industry of the country. Sri Lanka’s total marine fish catch amounted to 415,490Mt (242,580Mt of coastal fish catch and 172,910Mt of Offshore and Deep-Sea fish catch). The inland and aquaculture fish production in 2019 was 90,340Mt. The total export volume of seafood and fishery products was 28,771Mt which brought in US$81.3 million in foreign exchange earnings.

Why You Should Choose Us

WE ARE OFFER,

- Sustainable and traceable products

- Reliable, on-time delivery

- Certified quality products

- Innovative solutions tailored to customer needs

- High-quality seafood sourced from Sri Lanka

- Optimized pricing strategies

- Flexible order customization, even on short notice

- Tailored packaging solutions

Why You Should Choose Us

WE ARE OFFER,

Sustainable and Traceable Products

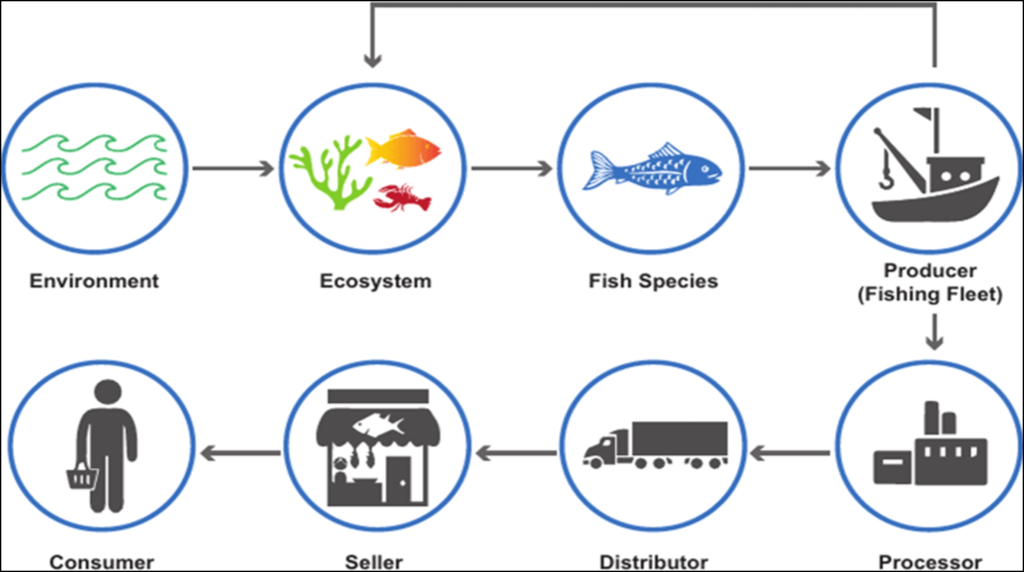

Our seafood products are sourced with care for the environment, adhering to strict sustainable fishing practices. Each product is fully traceable from catch to delivery, ensuring transparency and quality at every step.

Reliable, On-Time Delivery

We prioritize timely delivery to ensure our seafood reaches you at peak freshness, maintaining our commitment to reliability and customer satisfaction with every order.

Solo & Team Fishing

Whether fishing solo or with a team, our expertise and resources support a rewarding, sustainable fishing experience tailored to your needs.

Fishing Reel

Our high-performance fishing reels ensure smooth casting and reeling, giving anglers precise control and reliability for every catch.

River Fishing

Enjoy the dynamic experience of river fishing with gear tailored for fast currents, ensuring stability, control, and success in every cast.

River Fishing

Enjoy the dynamic experience of river fishing with gear tailored for fast currents, ensuring stability, control, and success in every cast.

River Fishing

Enjoy the dynamic experience of river fishing with gear tailored for fast currents, ensuring stability, control, and success in every cast.

Shop

From Fresh Tuna and Swordfish to Exotic Reef Fish and Crustaceans, our wide range of products caters to diverse tastes and culinary needs, each sourced responsibly and processed with care.

Fishing Reel

Our high-performance fishing reels ensure smooth casting and reeling, giving anglers precise control and reliability for every catch.

River Fishing

Enjoy the dynamic experience of river fishing with gear tailored for fast currents, ensuring stability, control, and success in every cast.

River Fishing

Enjoy the dynamic experience of river fishing with gear tailored for fast currents, ensuring stability, control, and success in every cast.

River Fishing

Enjoy the dynamic experience of river fishing with gear tailored for fast currents, ensuring stability, control, and success in every cast.

Our Working Process

East Bay International’s seafood processing involves a series of meticulous steps, from initial quality assessment, gilling, and filleting, to final vacuum packing and chilled storage, ensuring premium quality.

1

Unloading, Grading & Sampling

Fresh seafood is promptly cleaned, graded by color and texture, and sent for chemical analysis in our lab, ensuring only the best quality meets our standards

2

Gilling, Gutting, and Filleting

After thorough cleaning, fish are prepared by removing gills, guts, tails, fins, and heads, followed by precise filleting for optimal quality

3

Trimming & Portioning

Each fillet is checked for imperfections and trimmed according to buyer specifications to ensure only top-quality cuts reach our customers

4

Vacuum Packing & Chill Storage

Products are vacuum-sealed, labeled, and stored in ice slurries at 0°C to preserve freshness until export.

Our Clients Says

Hear from our valued clients who trust East Bay International for consistently high-quality seafood, exceptional service, and our commitment to sustainability. Discover why we’re a preferred partner in the global seafood industry.

"Our clients praise our attention to detail and unwavering commitment to quality—see why East Bay is trusted worldwide."

Executive Chef, Italy

"Customer satisfaction drives everything we do. Read how we’ve exceeded expectations with our fresh, sustainably sourced seafood."

Supermarket Chain Buyer, Germany

"East Bay International’s reliability and quality are unmatched. Explore testimonials from those who count on us for premium seafood."

Import Manager

"Our commitment to sustainable practices has earned us global trust. Discover how our approach impacts our clients and their markets."

James R.

Seafood Distributor, UK